Plastic tube Making/ Finishing

Tube Finishing

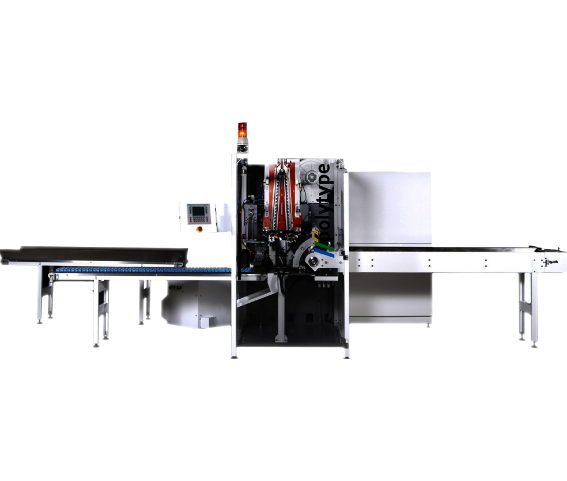

RHM 300

Flexible and modular finishing machine for cylindrical and oval plastic tubes

Flexible and modular finishing machine for cylindrical and oval plastic tubes

RHM 200

Flexible and modular tube finishing machine for cylindrical and oval plastic tubes with the possibility of labeling

Flexible and modular tube finishing machine for cylindrical and oval plastic tubes with the possibility of labeling

RHM 150

The flexible and modular tube finishing machine for cylindrical plastic tubes

The flexible and modular tube finishing machine for cylindrical plastic tubes

RHM 100

The flexible and modular tube finishing machine for cylindrical plastic tubes with the possibility of labeling

The flexible and modular tube finishing machine for cylindrical plastic tubes with the possibility of labeling

CM 130

The flexible and modular tube finishing machine for cylindrical plastic tubes with the possibility of labeling

The flexible and modular tube finishing machine for cylindrical plastic tubes with the possibility of labeling

Flexible and modular tube finishing machine for cylindrical and oval plastic tubes

Highlights:

- Machine design for quick changes and easy maintenance

- Control station with graphic and text display

- Memory of recipes

- Statistics tool (process control on the display)

Flexible and modular tube finishing machine for cylindrical and oval plastic tubes with the possibility of labeling

Highlights:

- Machine design for quick changes and easy maintenance

- Control station with graphic and text display

- Memory of recipes

- Statistics tool (process control on the display)

The flexible and modular tube finishing machine for cylindrical plastic tubes

Highlights:

- Machine design for quick changes and easy maintenance

- Control station with graphic and text display

- Memory of recipes Statistics tool (process control on the display)

The flexible and modular tube finishing machine for cylindrical plastic tubes with the possibility of labeling

Highlights:

- Machine design for quick changes and easy maintenance

- Control station with graphic and text display

- Memory of recipes Statistics tool (process control on the display)

The standard tube-finishing machine

Operations:

- Membrane sealing

- Cap snap-on with/without positioning

- Cap screw-on

- Cap tightening

Highlights:

- Machine design for quick changes and easy maintenance

- Control station with graphic and text display

- Memory of recipes Statistics tool (process control on the display)

Technical Data

RHM 300 | RHM 200 | RHM 150 | RHM 100 | CM 130 | |

|---|---|---|---|---|---|

Min./max. diameter

| (10) 19-50 mm

| 19-50 (60) mm

| 19-50 (60) mm

| 19-50 (60) mm

| 19-50 (60) mm

|

Skirt length

| 60-215 mm

| 60-215 mm

| 60-215 mm

| 60-215 mm

| 60-215 mm

|

Cap diameter

| 8-50 mm

| 19-50 mm

| 19-50 mm

| 19-50 mm

| 19-50 mm

|

Max. printing speed

| 300/min*

| 200/min*

| 150/min*

| 100/min*

| 120/min*

|

Weight of main machine | 8500 kg*

| ~7000 kg*

| 6000 kg*

| ~ 5500 kg*

| ~ 2500 kg*

|

Horizontal mandrel machine with 16 quick-change mandrels | Horizontal mandrel machine with 16 quick-change mandrels | Horizontal mandrel machine with 8 quick-change mandrels |

*(depending on configuration)

Ready to get in touch?

Whether you have questions, feedback, or partnership inquiries, we’re here to listen.

Reach out to us and let’s start a conversation that leads to possibilities.