Plastic container decoration

Dry Offset Round

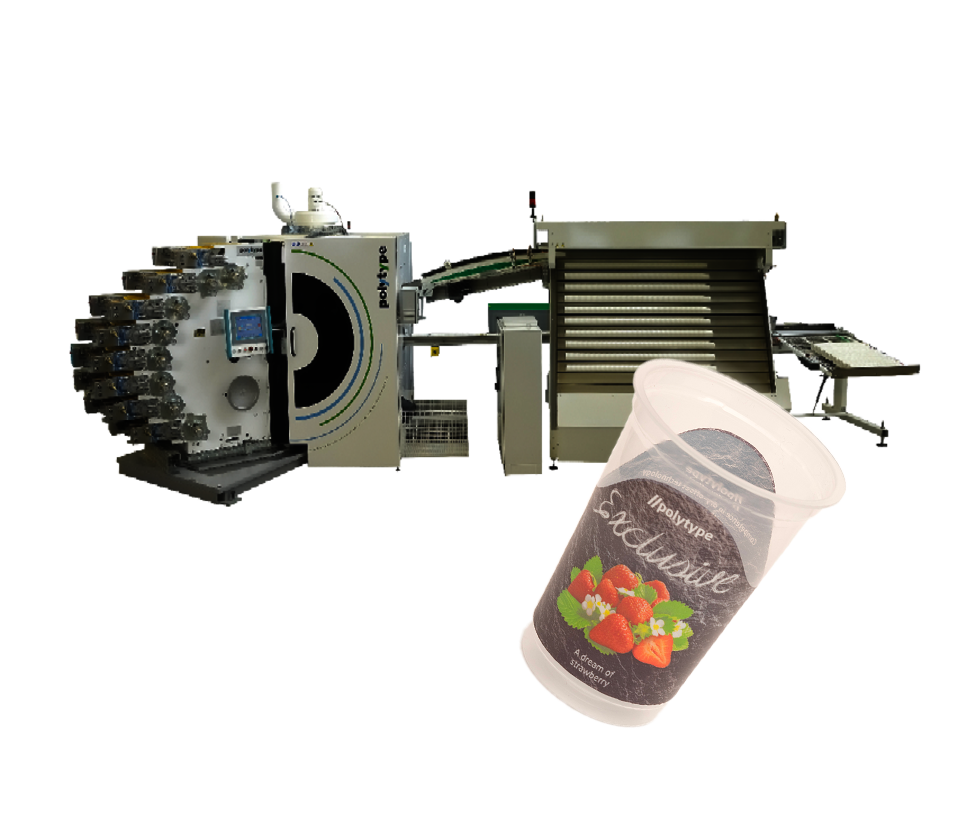

high-performance cup printing systems

The standard cup dry offset printing machine with high reliability

High-performance dry offset printing machine for round cups

High-performance dry offset printing machine for round bucket

The standard cup dry offset printing machine with high reliability

The 6-8 color cup printing system, type BDM 482, is a proven concept. The basic printing unit and transfer section are made of a robust steel construction. The pre-treatment and the UV-Mandrel curing are integrated in the basic machine concept. The standard cup infeed and discharge automation round off the system.

Good to know

- High user-friendliness: printing unit and transfer accessible from one side

- Layout with in-feed elevator

- Semi-Automatic inking unit washing

- Analog display of the printing unit angle position

- Pre-print system for transparent cups

High-performance dry offset printing machine for round cups

The high performance 6-8 cup printing system, type BDM 681/682 for round cups. The basic printing unit and transfer section are made of a robust steel construction. The pre-treatment and the UV-Mandrel curing are integrated in the basic machine concept. The newly designed cup in-feed and discharge automation round off the system.

The main characteristics of BDM 681/682 printing technology are the very high efficiency, the outstanding print quality, the short change-over time as well as the excellent accessibility and ergonomics (one operator layout).

High-performance dry offset printing machine for round bucket

The high performance 6-8 cup printing system, type BDM 930 for round bucket. The basic printing unit and transfer section are made of a robust steel construction. The pre-treatment and the UV-Mandrel curing are integrated in the basic machine concept. The flexible feeding system open the possibility to print on different products.

Technical Data

BDM 482 | BDM 681/682 | BDM 930 | |

|---|---|---|---|

Min./max. cup height | 35 – 200 mm | 35 – 200 mm | 75 – 300 mm |

Min./max. rim diameter

| 60 – 185 mm

| 60 – 185 mm

| 50 – 300 mm

|

Max. printing width

| 145 mm

| ||

Max. printing length

| 345/502 mm (6/3 sections)

| 418/502 mm | 800 mm

|

Max. print height

| 145 mm | 200 (260) mm

| |

Min. / max. taper

| 2-15°

| 2-15°

| 2-10°

|

Max. printing speed

| 27,000 / h

| 650 cups/min

| 300 cups/min

|

Weight of main machine

| ~6,500 kg

| 6,500 kg

| |

Standard options

| – Layout with in-feed elevator – Second application roller for inking unit – Analog display of the printing unit angle position – Pre-print system for transparent cups | – Package for FAST CHANGE-OVER – Pre-print system complete – Positioning device for two compartment container or with lips – LED Curing – Vision control system | |

Highlights | – Very high productivity and quick set-up time – Easy access and operator safety – Very user-friendly and easy to operate |

Ready to get in touch?

Whether you have questions, feedback, or partnership inquiries, we’re here to listen.

Reach out to us and let’s start a conversation that leads to possibilities.